Improved warehouse storage with Modula vertical lift modules and Bulldog Push Back racking.

Background:

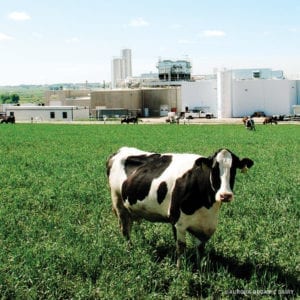

Client: Aurora Organic Dairy (AOD)

Markets: Industrial

Products: Modula vertical lifts, Bulldog pushback racks

Completion: June 2018

The leading producer and processor of store-brand organic milk and butter for U.S. retailers. Based in Boulder, Colorado, AOD operates organic dairy, heifer, and calf farms in Colorado and Texas, as well as an organic dairy processing plant in Platteville, Colorado. In early 2019, they will begin operations on a second milk plant in Columbia, Missouri.

Working with the AOD staff to find the right solution for their operations

Challenges

Aurora Organic Dairy was building a new processing and storage facility in Columbia Missouri to expand their operations into the Midwest. They needed refrigerated warehouse storage, pallet racking, and vertical storage that maximized their new space.

Their facility is a long and narrow warehouse to store all the dry goods product and produce their organic food offerings, making storage challenging. They also wanted to store milk samples in both cold and warm storage. They needed a storage system that would compliment their operations, while utilizing their space to maximize storage.

Our design solution

Push Back Racking for Pallet and Dry Good Storage

We originally tried to layout a high density mobile pallet rack system to improve the storage capacity. However, it ended up more cost effective to use push back racking to store their fast moving products. We customized beam levels to accommodate specific pallet sizes for different products. We even installed racking above the emergency exit to maximize storage.

Vertical lift machines for parts storage and product samples

Aurora Organic Dairy are using two Modula Vertical Lift Machines (VLMs) to store maintenance parts for all their dairy processing equipment. The VLMs not only save space, but significantly reduce picking time through automated storage and retrieval (ASRS).

The other two VLMs are in the product sample testing area. One of the units is designed for cold storage and one warm storage. The outer skins were left off of the units above nine feet to allow the warm or cold air circulate via custom HVAC ducts (see images below). The samples are accessed through the wall in the testing lab. These VLMs storing product samples incorporate the same ASRS benefits.