Industrial Automation Solutions

Automated, modern solutions for transforming industrial facilities and revolutionizing every day processes.

Revolutionize Your Warehouse with Advanced Industrial Automation Solutions

We’re committed to transforming your warehouse with cutting-edge automated solutions. Wouldn’t it be great to boost productivity by up to 85%, and save up to 90% of your floor space?

Reclaim unused space and invest in efficiency with industrial automation solutions such as ASRS Pallet Shuttles or Vertical Lift Modules. Embrace the future of order fulfillment with Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). Discover how Pick Modules, Conveyors, and Warehouse Software systems can elevate your order workplace to new heights.

- Increased Efficiency and Throughput: Perform repetitive tasks much faster and more consistently than humans, leading to higher speed and output.

- Improved Inventory Management: Real-time tracking of inventory, preventing stockouts, reducing surplus, and valuable data for decision-making.

- Reduced Labor Costs: Decrease reliance on manual labor, leading to lower payroll expenses and allowing existing staff to focus on more complex roles.

- Improved Profitability: Increased productivity, higher throughput, and better inventory control = improved profitability and a stronger ROI!

- Scalability: Easily scale up or down to meet fluctuating demand, providing flexibility without requiring temporary staff.

Connect with Bradford Systems

Fill in below form as complete as possible and one of our representative will be in touch with you shortly

Modula Vertical Lift Modules: Automated VLM Storage Solutions For Every Need

Modula’s Vertical Lift Modules (VLMs) are vertical storage ASRS that take up a minimum footprint by utilizing the ceiling height available. These systems allow for large inventory of goods to be quickly accessible while being stored in a safe and secure environment and automatically delivered to the operators, with a simple touch on the user friendly Copilot controller or the scan of the barcode.

- Saves Space & Reduces Operations Cost: Saves up to 90% of valuable floor space compared to traditional storage methods.

- Increased Capacity: Throughput of up to 130 trays per hour and a tray payload capacity of up to 2,200 lbs!

- Process More Orders in Less Time: Increase productivity up to 85%. One worker is able to handle the same volume previously performed by multiple operators.

Deep-Lane Pallet Storage: 2D, 3D, and 4D Automated Guided Vehicles (AGVs)

Pallet Shuttles are an ASRS that increase storage density and efficiency by automating deep-lane storage. This reduces operating costs through labor reduction and energy savings, and improve safety by minimizing forklift traffic and human interaction in aisles.

- Versatility: While 2D shuttles move within a lane, 4D (or four-way) shuttles can travel horizontally and vertically across multiple aisles.

- Turn-Key Solution: These systems can often be integrated into existing warehouses, making them a flexible solution for modernization.

- Flexibility: Can support both FIFO (First-In, First-Out) and FILO (First-In, Last-Out) inventory rotation, providing flexibility for different product types.

- Sustainability: Higher storage density reduces the overall footprint of the warehouse, leading to lower energy consumption for lighting, heating, and cooling.

Vidir's Vertical Carousels & Lifts: Industrial strength automated Storage for Any Material

Vidir offers vertical inventory management solutions for all industries using Vertical Lift storage to maximize capacity within a minimal footprint, making it a practical option for facilities looking to improve inventory management and efficiency. These industrial storage systems integrate seamlessly with warehouse automation programs, delivering measurable improvements in both productivity and safety.

- Dual-Tower Sheet Metal VLS

- Pan Carousel

- Wire Spool Carousel

- Shelving Carousel

- Bar Stock VLS

- Tire Carousels

- Hospital Bedlift

- Textile Carousels

- Sports Equipment Lifts

- Motorized Flooring Cutters

Transform order Fulfillment with ASRS Robots: Advanced autonomous mobile robots (AMRs)

In the rapidly evolving world of logistics, we’re proud to partner with leaders at the forefront of warehouse automation offering innovative AMR (Autonomous Mobile Robot) systems designed for warehouse automation and e-commerce fulfillment: Picking, Putaway, Point-to-Point Transport, Warehouse Management, Sorting, and more. Browse our incredible ASRS offerings…

- RackBot™ Tote AMR

- Shelf-to-person AMR

- Goods-to-person AMR

- Locus Origin & Vector

- Intelligent Sortation AMR

- Totes-to-Person AMR

- Inventory Management AMR

- AGI Sorting Bot

Modula's Horizontal Carousel

Modula’s Horizontal Carousel (HC) is the ideal solution when you need high-speed picking in a low ceiling environment. The carousel consists of carriers (bins) mounted on an oval track that rotate horizontally and deliver stored goods to the picker.

- Without the need to travel across a warehouse for items, productivity skyrockets, with picking rates of up to 550 lines per hour.

- Provide the safest working environment by reducing physical strain, and eliminating wasteful travel around the warehouse.

- With simple visual picking aids, users can quickly identify the item and quantity to pick, improving accuracy up to 99%.

- All picking operations are monitored and documented, providing full traceability of orders and tracking stock levels in real time.

Innovative Solutions: Warehouse Management & Logistics Software

Warehouse Management Systems (WMS) are software solutions that provide visibility and control over warehouse operations, including inventory, receiving, storage, picking, packing, and shipping. These systems optimize warehouse processes, automate tasks, and ensure efficient inventory flow.

- Helps optimize warehouse layout, picking routes, and other processes to improve workflow and safety.

- Streamlines the processes of picking, packing, and shipping orders to customers.

- Offers real-time data and insights into warehouse operations, allowing for better decision-making.

Levi Mover

An autonomous forklift designed for smart warehouses, Levi Mover efficiently loads and unloads pallet ASRS systems across sectors like grocery, F&B, and industrial logistics. With precise navigation and a high payload capacity, it eliminates manual handling, increasing safety and productivity.

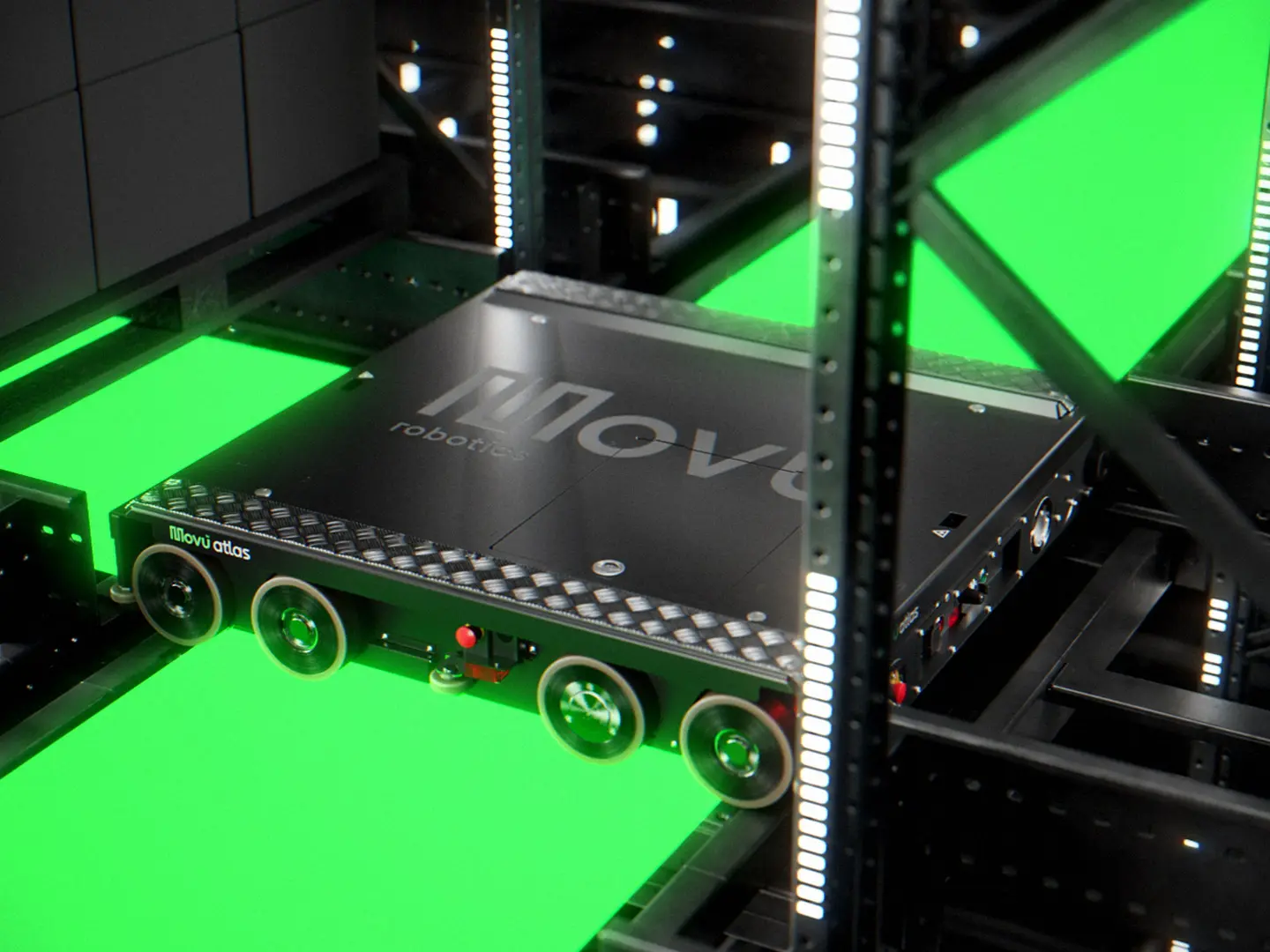

Autonomous Mobile Robot (AMR)

Innovate your warehouse operations with our Autonomous Mobile Robot by Stow, Movu. Adaptable and scalable, it seamlessly integrates into your workflow, enhancing productivity and safety. Ideal for collaborative picking or pallet transport, our AMR reduces picking errors and adapts to various layouts.

Advance your operations with autonomous efficiency

Work Smarter: Pick Modules Integrated within Your Facility infrastructure

Pick Modules are multi-level, high-efficiency storage and picking zones engineered for throughput inventory. Customized to your inventory specifications and operational needs, these systems can integrate gravity flow racking and conveyors to streamline product movement—from order picking to shipping. Maximized productivity, accelerated pick rates, and optimized labor resources. Combine a variety of components:

- Storage Racks: Pallet racks, carton flow, pushback, and shelving units.

- Mezzanines and Rack-Supported Levels: To create multi-level picking zones.

- Conveyor Systems: Powered or gravity-fed conveyors to transport items for packing.

- Pick Stations: Areas equipped with technology for efficient order assembly.

Streamline Operations with Pick Stations & Picking Robots

To handle batch or multiple order processes, a Picking Station keeps everything moving. Use one or several at predetermined put positions. The Picking Robot’s versatility, which allows it to identify, pick, and place a wide range of items, makes it well-suited for various requirements. Designed to meet the needs of any warehouse operations, these options easily integrate with both manual or automated handling systems like belt conveyors.

- Interlake/Mecalux Picking Robot

- Modula's Picking Station

- SIMATIC Robot Pick AI

- Mushiny 3D Sorter MINI/MAX

- Locus multi-bot Fleets

- Modula Put to Light System

Mini-Load Systems, Mezzanine Management, ASRS Cranes & more

Revolutionize your industrial operations with our premier selection of essential technology for optimizing material handling processes. From robotics to cranes, conveyors, shuttles, and software, we’ve got you covered. Reach out to our industrial planning experts today to find out how Bradford Systems can customize the perfect solution for your facility!

Material Movement Made Simple: Modern Conveyor Systems

We know the right design for a manufacturing, distribution, or warehousing facility can save millions over the course of its operation. Conveyors are one of the technologies that can help. Whether handling cases, totes, polybags, jiffys or parcels, each system should be designed with the right mix of transportation, accumulation, and intelligent handling conveyor to fit your operations.

- High-Speed Merge & Inductions

- Narrow Belt Live Roller

- Belt Conveyor

- V-Belt Live Roller

- Motor Driven Roller

- MoveIT-Max™

Industrial Automation Products – FAQs

Automated solutions such as vertical lift modules (VLMs), ASRS, and robotic retrieval systems that streamline material handling.

They save space, reduce labor costs, boost picking speed, and improve inventory accuracy.

E-commerce, manufacturing, aerospace, automotive, and logistics operations.

Yes. Automation seamlessly connects with warehouse and enterprise systems for full visibility.

Absolutely. Systems can be deployed in phases and expanded as demand grows.