The manufacturing sector is poised for one of its most transformative years. With global labor shortages, rising customer expectations, supply-chain complexity, and the continual drive for efficiency, manufacturers are turning to industrial automation and automated solutions not as optional upgrades, but as strategic imperatives. In 2026, operations that harness smart storage, robotics, data analytics, and warehouse automation will leap ahead of the competition.

This article explores what manufacturing and warehouse operations can expect over the next year, covering predictions, trends, and practical recommendations. It highlights how Bradford Systems is positioned to deliver solutions that enhance precision and evolve with the new era of manufacturing automation.

Industry 4.0 Becomes the Baseline for Smart Factories

The term “Industry 4.0” once evoked futuristic visions; now it is fast becoming the baseline expectation for manufacturing operations. By 2026, connected machines, sensor-driven workflows, and real-time decisioning will no longer be optional—they will be foundational specifications.

According to a 2026 outlook from Deloitte, 80% of manufacturing executives expect to invest at least 20% of their improvement budgets in innovative manufacturing initiatives, including automation hardware, sensors, data analytics, and cloud technologies. Coupled with this, the firm projects that “agentic AI” (systems that can reason, plan, and act autonomously) will grow strongly in production facilities.

For storage, material handling, and inventory workflows, this means the systems you design today must integrate seamlessly with digital ecosystems rather than operate in isolation.

How Bradford Systems can help: Bradford’s industrial storage and automated solutions are built for connected environments. Whether it’s automated vertical lift modules, robotics-compatible storage, or intelligent shelving, these systems connect into your holistic smart-warehouse architecture and support future workloads.

Robotics, Cobots, and Mobile Automation Scale Rapidly

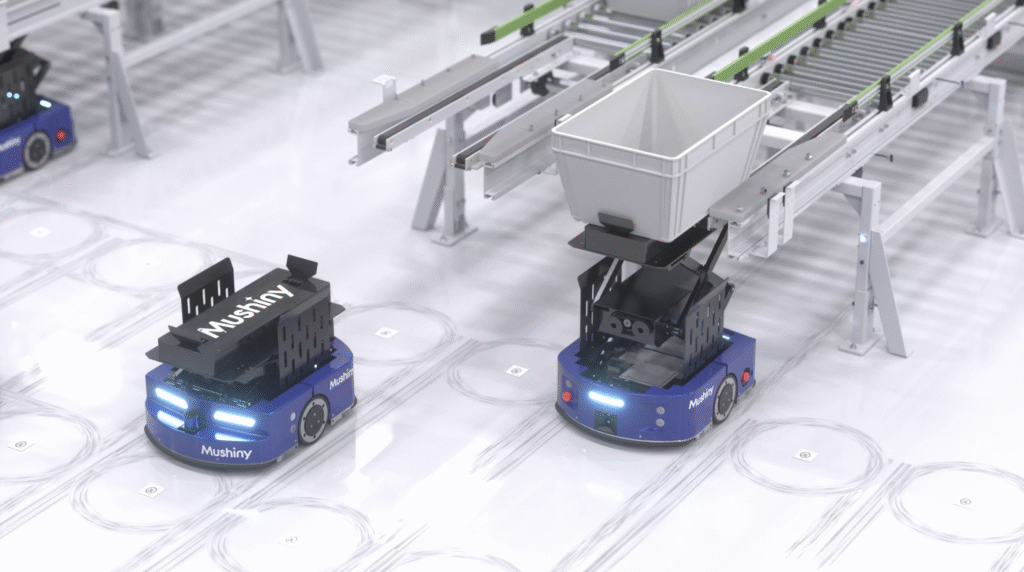

Robotics adoption is no longer a niche; by 2026, it will be widespread. The rise of collaborative robots (cobots) that work side-by-side with human operators and mobile robots that autonomously transport goods in real time will change how material flows through a manufacturing or warehouse facility.

An insight piece on factory automation identifies four major trends reshaping facilities: mobile robotics, AI-driven perception, cybersecurity-by-design, and hyper-flexible equipment. Meanwhile, market data shows the global industrial automation market is estimated at USD 233.6 billion in 2026, up from USD 215.2 billion in 2025, and growing at a ~9.5% CAGR through 2035.

This growth emphasizes that robotics and automated equipment will increasingly handle material movement, retrieval, and production tasks—meaning manufacturers must plan for how storage and handling systems integrate with robotics.

Bradford Systems solutions: Our automated storage modules (vertical lifts, horizontal carousels, mobile shelving) are designed to be compatible with robot-enabled workflows. By centralizing parts or materials in retrieval-friendly systems, automated workflows can operate more efficiently with fewer human interruptions.

Warehouse Automation and the Rise of Smart Storage

Warehouse automation and advanced storage systems will drive significant gains in 2026. As manufacturing operations increasingly include in-house warehousing and shipping, and as supply-chain timing tightens, the demand for automated solutions in storage, retrieval, and inventory management becomes paramount.

According to warehouse/automation analyses, facilities will shift to software-driven, real-time inventory management, goods-to-person systems, and higher storage density. Automated storage, compact racking, mobile shelving, and high-density systems will all be key strategies.

Bradford Systems support: With offerings such as high-density mobile racking, vertical lift modules (from partners like Modula), and automated retrieval systems, we’re here to help manufacturing and warehouse operations in reclaiming valuable floor space, reduce travel time, shorten pick cycles, and improve accuracy—all foundational for an automation-driven future!

AI and Analytics Drive Proactive Decision Making

In 2026, the shift from reactive to proactive operations will accelerate. AI, machine learning, and advanced analytics will be embedded into production, quality, maintenance, and supply chain workflows.

The Deloitte outlook specifies that agentic AI can help manufacturers “maximize production uptime with autonomously generated shift handover reports and work instructions.” At the same time, academic research shows that AI adoption in manufacturing is rising meaningfully, though still early-stage.

For industrial environments, this means your automated solutions must feed data—not just operate in isolation. Storage systems, robotics workflows, and warehouse automation must generate and share data so that AI-driven decision tools can deliver insights such as inventory forecasting, predictive maintenance, and workflow optimization.

How Bradford aligns: Bradford Systems’ automated storage platforms integrate with warehouse management, WMS software, and ERP systems to provide visibility into material flows, cycle times, and throughput. This data foundation supports AI analysis and helps prepare your operations for the next wave of automation intelligence.

Smart Storage Becomes Integral to Automation Strategy

Industrial storage is evolving from passive racks to active components within IoT automation strategies. Intelligent storage systems will include sensors, software integration, retrieval automation, and connectivity to robotics and comprehensive warehouse systems.

The market for industrial sensors—fundamental to storage automation—is forecast to grow as manufacturers push for Industry 4.0 adoption. Storage systems will not just hold parts—they will actively support retrieval, monitoring, security, and data flow.

Bradford Systems’ automated industrial storage offerings: Equipment such as vertical lift modules, horizontal retrieval systems, and robotic ASRS technology provides compact, automated, retrieval-friendly storage for distribution centers. These systems increase density, reduce retrieval time, integrate with robotics, and support modern manufacturing automation requirements.

Sustainability, Energy Efficiency, and Space Optimization

As costs rise and environmental targets tighten, manufacturers are turning to automation and smart storage not only for efficiency, but also for sustainability. Automated systems, such as conveyors & carousels, reduce energy consumption (by using fewer forklifts, less travel, and optimized lighting and space), lowering both costs and the carbon footprint.

Automated high-density storage reduces the footprint required for inventory holds, which means less warehouse space to maintain, heat, cool, or light, and more efficient use of pallets. The benefits are multiplied when these systems integrate into smart factory, distribution center, logistics, and warehouse automation strategies.

Bradford Systems solutions: With high-density mobile storage, vertical lift modules, storage bins, and optimized shelving, your business can reclaim floor space, minimize redundant travel, and improve material-flow efficiency. These gains help support broader sustainability goals & productivity.

Cybersecurity Becomes Fundamental to Automation

As connectivity across machines, sensors, robotics, storage systems, and software increases, cybersecurity in supply chains is no longer optional—it is a core component of automation readiness. Cyber-incident risk rises in automated, connected manufacturing environments.

According to trend research, “cybersecurity-by-design” is one of the four major trends reshaping factories in 2026. Manufacturers must ensure their automated storage systems, robotics interfaces, warehouses, and connected equipment include secure architecture, vendor updates, encrypted communication, and regular audits.

Bradford Systems offers: When implementing automated storage solutions, we’ll ensures integration with secure IT/OT networks and supports an architecture aligned with best-practice cybersecurity frameworks. This allows manufacturers to scale automation with confidence.

Workforce Evolution and Change Management

Automation doesn’t mean fewer workers—it means different roles. As manufacturing and warehouse automation scale, labor will shift toward oversight, programming, maintenance, analytics, robotics supervision, and process optimization.

For example, Deloitte highlights talent and workforce planning as key elements in their 2026 outlook. Training programs, human-machine collaboration, and change-management frameworks will be essential for success in manufacturing automation.

Bradford Systems’ role: By reducing physical strain, centralizing inventory, and automating retrieval, Bradford’s solutions enable human workers to perform more value-driven tasks rather than repetitive manual handling. This supports a safer, higher-skilled workforce and smoother adoption of automation.

Key Recommendations for Manufacturing Operations

- Evaluate current bottlenecks: Map your material flows, storage utilization, pick cycles, and identify where automation and storage density improvements will deliver swift ROI.

- Adopt innovative storage systems: Solutions such as automated vertical lift modules, mobile shelving, and robotics-compatible retrieval systems deliver immediate gains in space, efficiency, and accuracy.

- Integrate systems: Choose equipment and storage that can communicate with your WMS/ERP and feed data for analytics. Not just hardware but connected software matters.

- Choose scalable automation: Start with flexible systems that can grow as your production evolves—many 2026 trends will accelerate further beyond the immediate year.

- Invest in workforce readiness: Training, change management, and human-machine collaboration are essential for long-term adoption.

- Prioritize security and sustainability: As you automate, ensure they are built into your plan, not afterthoughts.

How Bradford Systems Can Help Your Industrial Facility Stay Ahead

Bradford Systems offers a full range of modern industrial storage and ASRS solutions designed for manufacturing, logistics, and warehouse automation. Whether your goal is to reclaim space, improve throughput, integrate robotics workflows, or future-proof material handling for 2026 and beyond, Bradford’s experts have the expertise and technology to partner with your facility successfully.

Key offerings include:

- Vertical Lift Modules and automated retrieval systems

- Robotic ASRS technology, such as AMR (Autonomous Mobile Robots)

- Warehouse automation-ready innovative storage systems

- Robotics-compatible storage equipment

- Customized solutions for manufacturing, aerospace, automotive, defense, and industrial sectors

- Support for software integration, data capture, and automated material flow

By partnering with Bradford Systems, businesses gain access to premier industrial solutions that align with the significant automation and warehouse trends for 2026. Let’s build your next-generation facility together!

Ready to transform your facility for the future? Reach out to Bradford Systems today for a consultation and see how our automated solutions and industrial storage expertise can drive operational efficiency and competitive advantage in 2026 and beyond.