Industrial operations today face a familiar challenge: how to balance limited floor space with the growing need for efficiency, safety, and speed. For manufacturers and fabricators working with heavy sheet metal, storage is often one of the biggest pain points. Traditional racks or floor stacking consume valuable square footage, slow down production, and increase the risk of injuries and material damage.

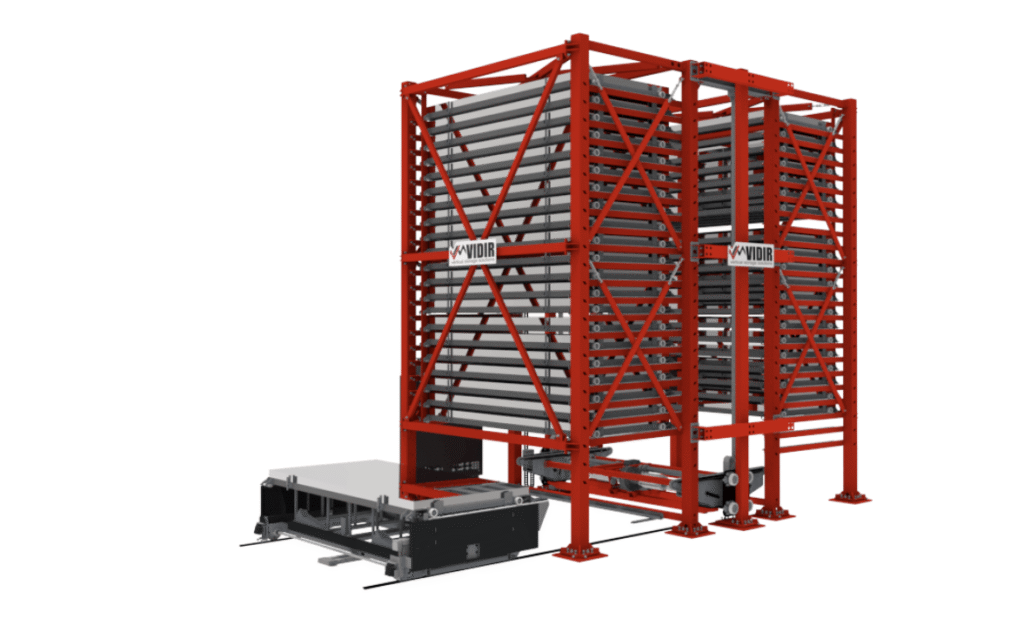

Bradford Systems is excited to announce a breakthrough solution that addresses these challenges head-on—the Dual-Tower Vertical Lift System (VLS) for sheet metal storage. This state-of-the-art innovation from Vidir takes automated vertical storage to the next level, helping you reclaim valuable floor space, boost productivity, and keep your team safe.

Why Vidir’s Dual-Tower Design Matters

Unlike standard storage systems, the dual-tower design maximizes capacity while keeping the footprint small. By working upward rather than outward, this system unlocks vertical space that would otherwise be wasted. Imagine reclaiming up to 80% of your floor space—space you could use to add new equipment, streamline your workflow, or expand production.

But the advantages don’t stop at space savings. The dual-tower configuration also provides better balance, more stability, and faster order fulfillment access to stored material, making it an ideal fit for high-volume, high-demand environments that utilize static shelving.

Key Advantages at a Glance

Here’s what makes the Dual-Tower Sheet Metal VLS stand out:

- High-capacity storage – Accommodates tens of thousands of pounds of sheet metal while occupying a fraction of the space.

- Automated retrieval – Brings materials directly to ground level, reducing manual handling and forklift use.

- Safer operations – Light curtains, emergency stops, and locking mechanisms protect operators during every lift.

- Preserved material quality – Sheet metal is stored in dedicated cartridges, reducing scratches, dents, and bending.

- Flexible setup – Configurable to handle common sheet sizes and adaptable to a variety of workflows.

- Made for growth – Scales easily as your production volume increases.

The Bigger Picture: Why This Innovation Matters for Manufacturers

For organizations handling sheet metal daily, storage isn’t just a logistics issue—it’s a direct factor in profitability. Poorly managed material can lead to:

- Wasted time searching for or retrieving sheets.

- Injuries and downtime are caused by risky handling.

- Damaged materials that eat into margins.

- Cluttered spaces that limit future growth.

By moving to an automated vertical storage system like the Dual-Tower VLS, manufacturers turn these pain points into opportunities. Instead of “making do” with crowded racks or floor storage, you gain an organized, safe, and scalable system designed for modern production.

Real-World Applications

The Dual-Tower Sheet Metal VLS can transform operations across multiple sectors:

- Fabrication shops need faster material access to keep machines running.

- Aerospace and automotive manufacturers where quality and precision are critical.

- Distribution and service centers that manage high volumes of varied sheet sizes.

- OEMs and heavy equipment manufacturers handling large panels and specialty metals.

- Facilities running out of space but looking to avoid costly expansions.

In each case, the system integrates seamlessly into existing workflows, cutting retrieval times and freeing up operators for higher-value tasks.

A Smarter Investment

Yes, a vertical lift system is a bigger upfront investment than traditional racks. But when you factor in:

- Freed floor space that delays or eliminates the need for facility expansion,

- Lower injury risk and reduced insurance exposure,

- Reduced scrap and waste, and

- Improved throughput,

…the payback becomes clear. Many organizations see a return in just a few years, along with lasting operational improvements.

Bradford Systems: Your Partner in Smarter Storage

At Bradford Systems, we don’t just deliver storage equipment—we help organizations rethink how they utilize their space with our automated system. As a trusted partner of Vidir, we’re proud to bring the Dual-Tower Sheet Metal VLS to manufacturers, fabricators, and distribution centers across the region.

Our team will work with you to:

- Assess your current space and workflow challenges.

- Model how a vertical lift system, including vertical carousels, would fit in your facility.

- Recommend the right configuration for your material mix.

- Support installation, training, and ongoing maintenance.

We’ve spent decades helping businesses unlock efficiency through smarter storage solutions—and this system is one of the most exciting advancements yet.

Conclusion

The new innovative Dual-Tower Sheet Metal VLS redefines what’s possible for sheet metal storage racks. With its space-saving design, safety features, and automation, it’s more than just a storage upgrade—it’s a strategic tool to drive productivity and growth.

If your facility is ready to step into the future of industrial storage, Bradford Systems can help you make it happen. Ready to transform your sheet metal storage? Contact Bradford Systems today to schedule a consultation. Our experts will help you design a smarter, safer, and more efficient storage solution tailored to your needs.