Efficient warehouse and industrial space management are critical components of a successful logistics operation. When you have the right layout strategies in place, you can maximize your storage capacity, streamline your operations, and improve overall productivity. In this blog, we’ll explore eight layout strategies for optimal space management in your warehouses.

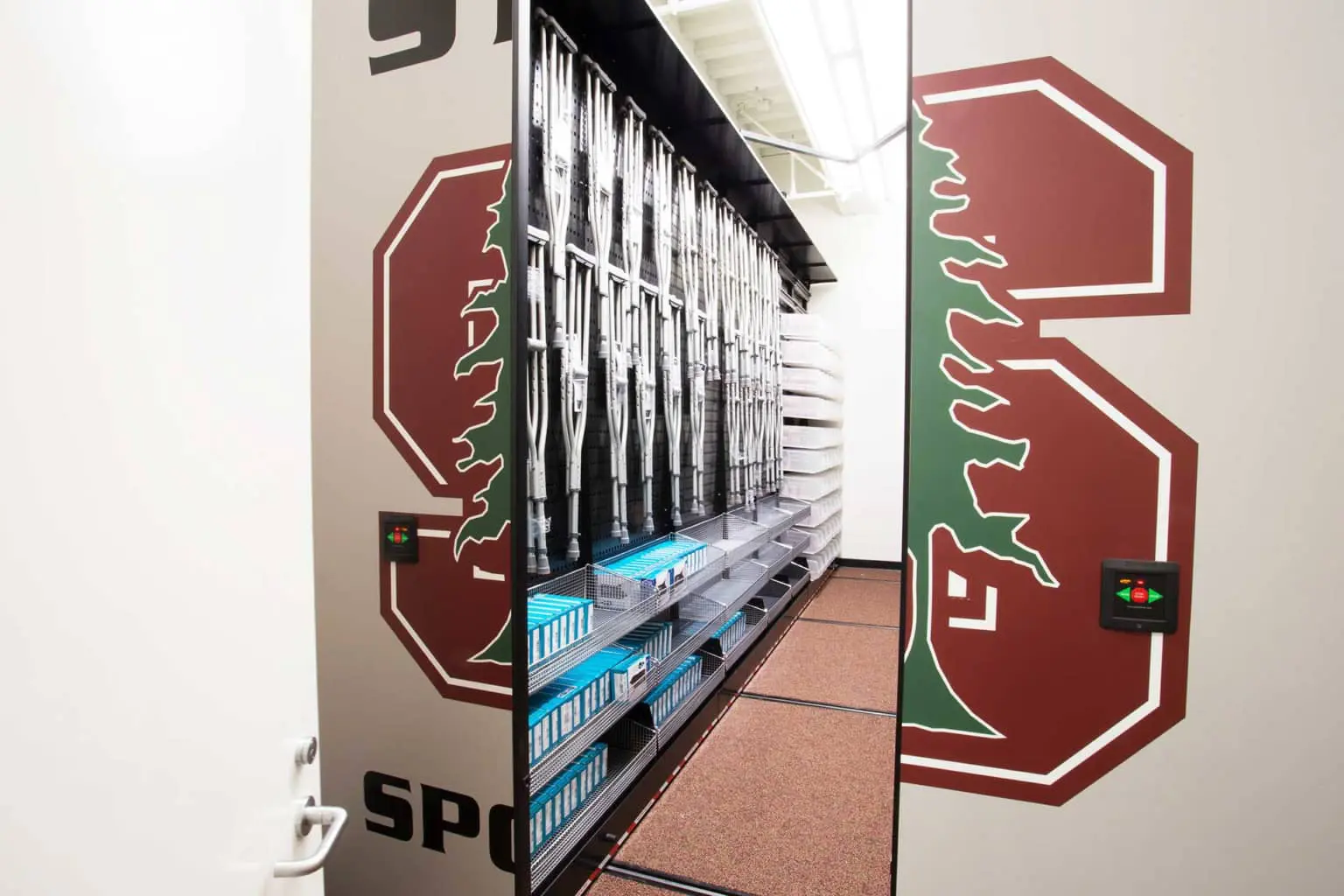

1. Utilize Vertical Space

One of the most effective ways to maximize your storage capacity is by utilizing vertical space. Consider installing tall storage racks or using mezzanine floors to increase the amount of usable storage space in your warehouse. By taking advantage of vertical space, you can reduce the amount of floor space needed for storage and free up room for other operations.

2. Use Standardized Storage Systems

Standardized storage systems like pallet racking or shelving can help you maximize your storage capacity while maintaining efficiency and productivity. When all your storage systems are uniform, it becomes easier to organize and access your inventory, reducing the time needed to locate and retrieve items.

3. Implement Zone Picking

Zone picking is a method of order picking that involves dividing your warehouse into zones, with each zone designated for a specific type of inventory. By implementing zone picking, you can reduce the amount of time needed for order fulfillment, as your workers only need to travel to a limited number of zones to fulfill an order.

4. Optimize Flow Paths

Optimizing the flow paths in your warehouse can help reduce congestion and improve overall productivity. Consider designing your warehouse with a clear and efficient flow path for your inventory and workers, minimizing the amount of travel needed to move items from one area to another.

5. Use Cross-Docking

Cross-docking is a process that involves unloading incoming inventory from a truck and immediately loading it onto an outbound truck for delivery. By using cross-docking, you can reduce the amount of time inventory spends in storage and improve overall throughput.

6. Implement Automated Storage and Retrieval Systems

Automated storage and retrieval systems can help you maximize your storage capacity while improving efficiency and reducing labor costs. These systems use robotics and automated technology to move inventory throughout your warehouse, reducing the need for manual labor and maximizing space utilization. Modula or Vidir

7. Use Slotting Optimization

Slotting optimization involves strategically placing inventory in your warehouse based on factors like popularity, weight, and size. By optimizing your slotting, you can reduce the amount of time and effort needed to locate and retrieve items, improving overall productivity and efficiency.

8. Prioritize Safety

Safety should always be a top priority in your warehouse layout and space management strategies. Ensure that all equipment and storage systems are properly installed and maintained and that your workers are trained to operate them safely. Implementing safety protocols and regularly reviewing them can help prevent accidents and injuries in your warehouse.

Implementing effective warehouse layout strategies is essential to maximizing your storage capacity and optimizing your operations. By utilizing vertical space and optimizing your warehouse equipment positioning, you can create a warehouse that is efficient, productive, and safe. To learn more about optimizing your warehouse layout and space management strategies, contact Bradford Systems today.

Contact Us for Industrial Space Management Services

Now that you’ve got an idea of how to implement automation into your industrial application, speak with the best industrial automation suppliers in the U.S., Bradford Systems. To learn how we can help relieve your warehouse automation needs, contact us here or call us at 1-800-696-345