In the world of industrial storage, where efficiency and organization are paramount, heavy-duty shelving stands as the unsung hero. These robust shelving systems form the backbone of industrial storage solutions, providing the sturdy framework needed to optimize space and manage inventory efficiently. In this blog post, we will delve into the significance of heavy-duty shelving in industrial settings and explore how they contribute to a well-organized and efficient workspace.

The Role of Heavy-Duty Shelving in Industrial Storage

1. Maximizing Space Utilization

One of the primary functions of heavy-duty shelving is to maximize the utilization of available space within a warehouse or industrial facility. Industrial spaces are often characterized by their vast areas, and efficient space management is crucial to make the most of these environments.

Heavy-duty shelving systems are designed to accommodate large and bulky items, pallets, and heavy loads. They offer multiple shelves, often adjustable, allowing for customization based on the size and shape of the items to be stored. This flexibility ensures that every inch of available space is utilized efficiently.

2. Enhancing Organization

Effective organization is vital in industrial storage settings to streamline operations and reduce the time spent searching for items. Heavy-duty shelving provides a systematic and structured approach to inventory management.

By categorizing items and placing them on labeled shelves or racks, workers can quickly locate what they need. This not only increases efficiency but also reduces the risk of errors and accidents associated with disorganized storage.

3. Supporting Heavy Loads

Industrial environments deal with substantial loads and materials daily. Heavy-duty shelving systems are engineered to withstand the weight of these heavy loads, ensuring the safety of both the stored items and the personnel working in the vicinity.

The structural integrity of heavy-duty shelving is a result of robust materials, reinforced frames, and sturdy supports. This durability allows for the safe storage of heavy machinery parts, equipment, raw materials, and other substantial items.

4. Facilitating Accessibility

Accessibility to stored items is a key consideration in industrial settings. Heavy-duty shelving units are designed to provide easy access to items, even when they are stored high above the ground.

Options such as adjustable shelving heights and the use of forklifts or pallet jacks allow workers to reach items on higher shelves without compromising safety. This accessibility speeds up operations and minimizes downtime.

5. Ensuring Safety and Compliance

Safety is paramount in industrial environments, and heavy-duty shelving plays a vital role in ensuring a safe workspace. These shelving systems are designed with load capacities that adhere to industry standards and safety regulations.

Additionally, they are often engineered with features like locking mechanisms and anti-tip systems to prevent accidents and injuries. Compliance with safety standards is crucial for avoiding workplace accidents and legal issues.

Types of Heavy-Duty Shelving Systems

Various types of heavy-duty shelving systems cater to different industrial needs. Here are some common types:

1. Pallet Racking: Pallet racking systems are ideal for storing palletized goods. They come in various configurations, such as selective, drive-in, and push-back racks, each designed for specific storage requirements.

2. Cantilever Racking: Cantilever racks are perfect for long and bulky items like lumber, pipes, and steel bars. They have open-fronted arms that make it easy to load and unload items.

3. Bulk Storage Shelving: Bulk storage shelving is designed for the storage of large, heavy items that don’t fit on traditional shelves. They often feature wide and deep shelves with high load capacities.

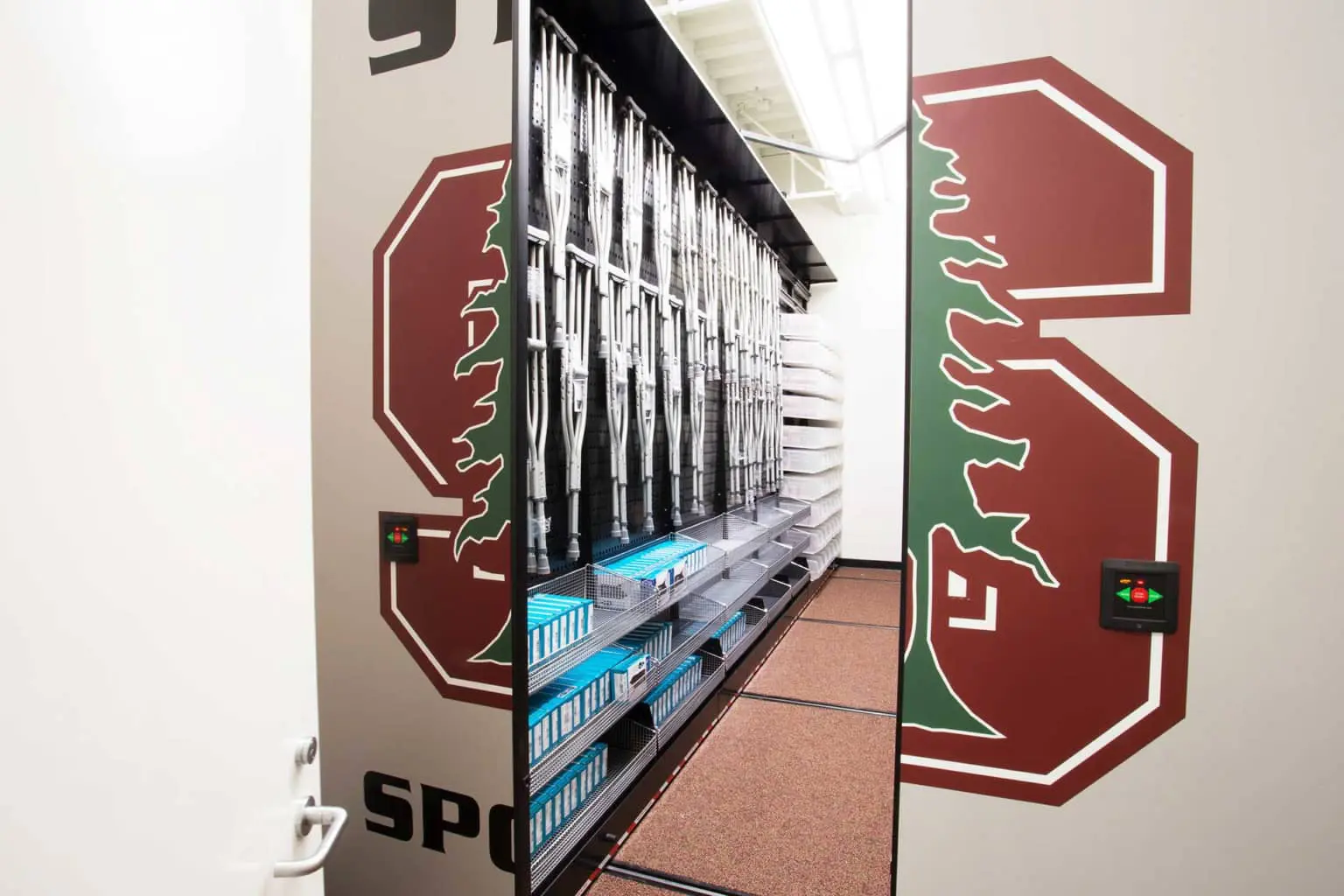

4. Mobile Shelving: Mobile shelving systems are mounted on tracks and can be moved horizontally to access stored items. They save space by eliminating the need for multiple aisles between shelving units.

Maintenance and Longevity

To ensure the longevity and reliability of heavy-duty shelving systems, regular maintenance is essential. This includes inspections for signs of wear and tear, lubrication of moving parts, and addressing any damage promptly.

Additionally, adhering to weight load limits and safety guidelines is crucial. Overloading shelves can lead to structural damage and safety hazards.

FAQ

Q1: What is the weight capacity of heavy-duty shelving?

A1: The weight capacity of heavy-duty shelving varies depending on the type and design of the shelving system. It can range from a few hundred pounds to several thousand pounds per shelf. Always check the manufacturer’s specifications for load limits.

Q2: Can heavy-duty shelving be customized to fit specific storage needs?

A2: Yes, many heavy-duty shelving systems offer customization options, including adjustable shelf heights and configurations. You can tailor the shelving to accommodate your specific storage requirements.

Q3: Are heavy-duty shelving systems suitable for small warehouses or workshops?

A3: Yes, heavy-duty shelving systems are adaptable and can be used in various industrial settings, including small warehouses and workshops. They provide efficient space utilization and organization, making them suitable for spaces of all sizes.

Q4: What safety measures should be taken when using heavy-duty shelving?

A4: Safety measures include adhering to weight load limits, regularly inspecting shelves for damage, ensuring that heavy items are stored securely, and using appropriate equipment (such as forklifts) for accessing high shelves. Follow all safety guidelines and regulations applicable to your industry.

Q5: Are heavy-duty shelving systems cost-effective in the long run?

A5: Yes, heavy-duty shelving systems are cost-effective in the long run due to their durability and ability to maximize space utilization. They reduce the need for additional storage space, making them a wise investment for industrial facilities.