As any automotive enthusiast or professional mechanic will tell you, the key to a successful project lies not just in having the right tools but also in keeping them organized and easily accessible. A cluttered and disorganized workspace can lead to frustration, wasted time, and even safety hazards. That’s where tool racks come into play, serving as the heartbeat of your automotive workspace. In this blog, we’ll explore the importance of tool racks, their benefits, and offer some valuable tips on how to optimize your automotive workspace for efficiency and convenience.

The Essence of Tool Racks

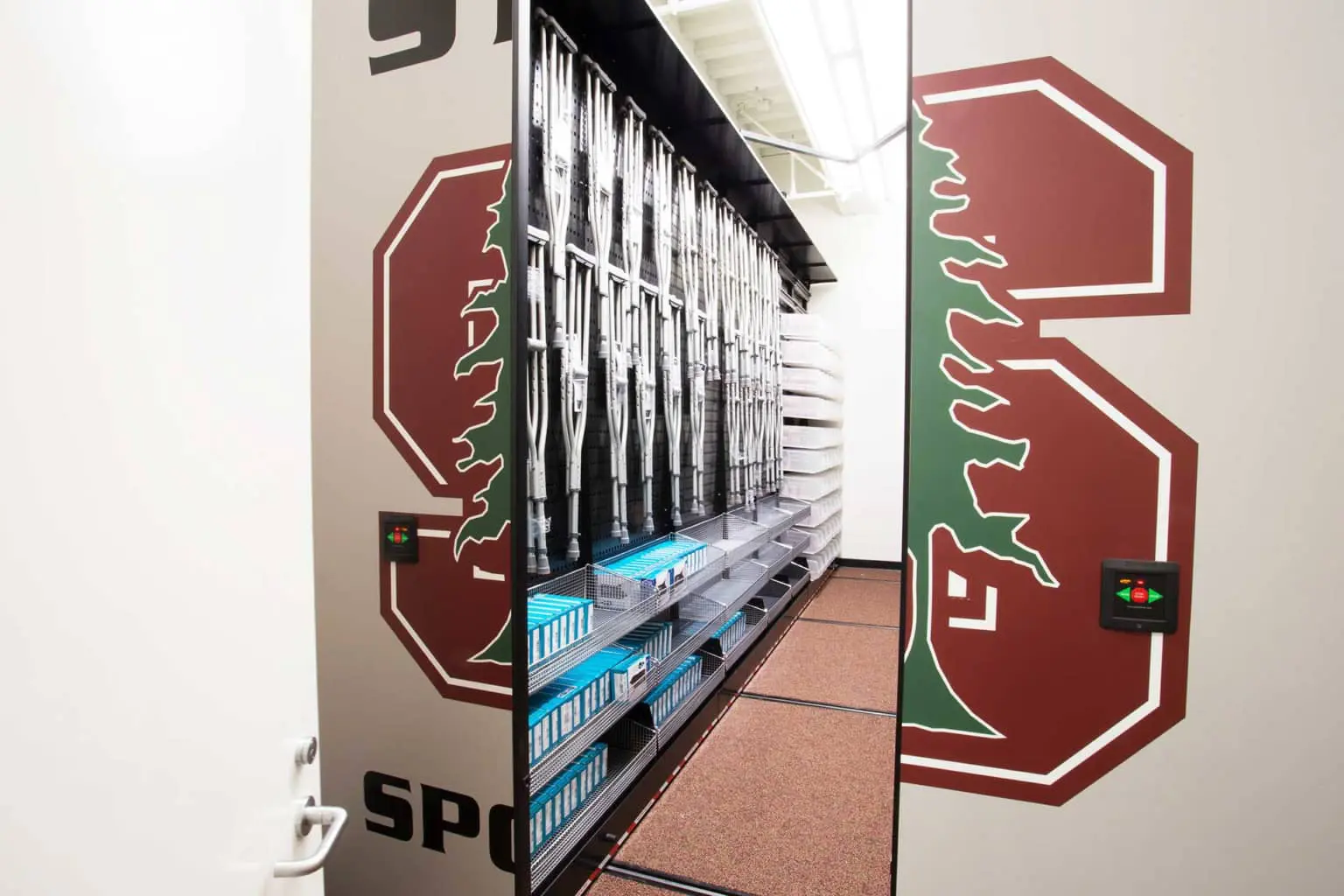

Tool racks are more than just storage solutions; they are the backbone of any automotive workspace. These racks provide a designated space for your tools, ensuring they are always within arm’s reach when you need them. Here are some compelling reasons why tool racks are indispensable in your automotive workspace:

Optimal Organization: Tool racks offer a systematic way to organize your tools. You can categorize and arrange your tools by size, type, or function, making it easy to find what you need quickly.

Space Efficiency: Tool racks are designed to maximize space utilization. They free up valuable workspace by keeping tools off the floor or workbenches, creating a clutter-free environment.

Enhanced Safety: A tidy workspace is a safer workspace. With tools properly stored on racks, the risk of tripping over them or accidentally knocking them off surfaces is significantly reduced.

Preservation of Tools: Storing tools on racks prevents them from coming into contact with moisture, chemicals, or abrasive surfaces, helping to prolong their lifespan.

Boosted Productivity: When your tools are organized and easily accessible, you can complete tasks more efficiently. No more wasting time searching for that elusive wrench or screwdriver.

Choosing the Right Tool Rack

Selecting the ideal tool rack for your automotive workspace is crucial. The choice depends on factors such as the size of your space, the types of tools you have, and your personal preferences. Here are some popular options:

Wall-Mounted Tool Racks: These racks are affixed to the walls of your garage or workshop, making excellent use of vertical space. They are perfect for smaller spaces and offer easy access to frequently used tools.

Rolling Tool Carts: If you need mobility in your workspace, rolling tool carts are a great choice. They come with wheels and multiple shelves or drawers for storing tools of various sizes.

Pegboards: Pegboards are versatile and customizable. You can arrange hooks, hangers, and shelves to fit your tools precisely. They are easy to install and allow for quick visibility of your tools.

Tool Cabinets: For a more comprehensive storage solution, tool cabinets with multiple drawers and compartments are excellent. They provide a clean and secure way to store your tools, protecting them from dust and debris.

Tips for Organizing Your Automotive Workspace

Now that you understand the importance of tool racks and have an idea of the types available, here are some tips to help you optimize your automotive workspace:

Plan Your Layout: Before installing tool racks, plan the layout of your workspace. Consider factors such as the proximity of your tools to your workbench, the flow of your tasks, and the accessibility of essential tools.

Label Everything: Labeling your tools and storage bins can save you a lot of time. Use clear, easy-to-read labels to quickly identify the contents of each rack or drawer.

Regular Maintenance: Make it a habit to clean and organize your tools regularly. Remove any tools or equipment that you no longer use and ensure everything has its designated place.

Safety First: Store sharp and dangerous tools out of reach of children or inexperienced individuals. Consider locking cabinets or drawers for added safety.

Invest in Quality Racks: Quality tool racks are a long-term investment. They are durable, sturdy, and can withstand the rigors of a busy automotive workspace.

Consider Ergonomics: Place frequently used tools at waist level to reduce bending and reaching. This ergonomic approach can help prevent strain and fatigue.

Personalize Your Workspace: Your automotive workspace is your domain. Customize it to reflect your style and preferences. Add a touch of personalization to make it an inspiring place to work.

FAQs

Q1: Are tool racks suitable for both home garages and professional auto repair shops?

A1: Absolutely! Tool racks are versatile and can be adapted to suit any automotive workspace, whether it’s a home garage or a professional auto repair shop.

Q2: Can I build my own tool rack, or should I buy pre-made ones?

A2: You can certainly build your own tool rack if you have the DIY skills and tools. Pre-made racks are convenient and come in various designs to meet different needs.

Q3: How can I prevent my tools from rusting when stored on a tool rack?

A3: To prevent rust, ensure your tools are clean and dry before storing them on a rack. Consider using rust-resistant coatings on metal tools and a dehumidifier in your workspace.

Q4: What’s the best way to organize small automotive accessories on a tool rack?

A4: Pegboards and small bins or containers are great for organizing small accessories. Labeling and categorizing these containers can help you find what you need quickly.

Q5: Can I use tool racks for power tools and larger equipment?

A5: Yes, many tool racks are designed to accommodate power tools and larger equipment. Look for racks with sturdy shelves or hooks capable of supporting the weight of your tools.

Conclusion

Tool racks are the unsung heroes of the automotive workspace. They offer organization, efficiency, and safety, allowing you to focus on what you love: working on cars. By choosing the right tool rack and implementing smart organizational strategies, you can transform your automotive workspace into a well-oiled machine, ensuring that you’re always ready for your next automotive adventure.